Rillito, AZ , January 14, 2017 – The CalPortland Rillito Cement Plant received an energy efficiency rebate check in the amount of $71,212.70 from Tucson Electric Power (TEP). TEP Commercial Energy Solutions program is an Arizona Corporation Commission approved program providing incentive funds for energy efficiency projects.

CalPortland is a construction materials company providing materials such as portland cement, ready mixed concrete, asphalt and aggregates for use in the western United States. CalPortland was founded in 1891 with the opening of the Colton California plant. The Rillito Cement Plant is a portland cement manufacturing plant which operates a limestone mine providing the raw materials necessary for the manufacture of portland cement. The cement process utilizes a rotary kiln for heating and processing the raw materials into an intermediate material which is called clinker, the clinker is heated to approximately 2500 degrees Fahrenheit, and when the clinker exits the kiln it must be rapidly cooled and conveyed to a storage facility. The cooling process will reduce the 2500 degrees F clinker to below 200 degrees F using ambient air provided by large fans that pull air into the cooling process. The cooling air absorbs heat from the clinker, and then the heated air is efficiently used as input air into the kiln process.

CalPortland identified an energy efficiency project that would reduce fuel and electrical consumption by replacing/improving the clinker cooler process. The cost of the CalPortland clinker cooler project was justified due to the availability of funds from the TEP Commercial Energy Solutions program.

The new clinker cooler utilizes many new technologies. Previous cooler fans were constant speed fans with louver controls for controlling the air flow rate. These fans were replaced with 7 new variable speed fans that provided increased efficiency by controlling the speed of the fan to control the air flow. A variety of other crushing and conveying technology upgrades were also implemented to increase the energy efficiency of the system.

CalPortland implements an Energy Management program that strives for performance efficiency in order to reduce operating costs. CalPortland has received energy efficiency rebates in many other states. To date, this is the company’s largest rebate in the state of Arizona. The team at TEP provided outstanding assistance during the rebate application process, of which CalPortland is grateful.

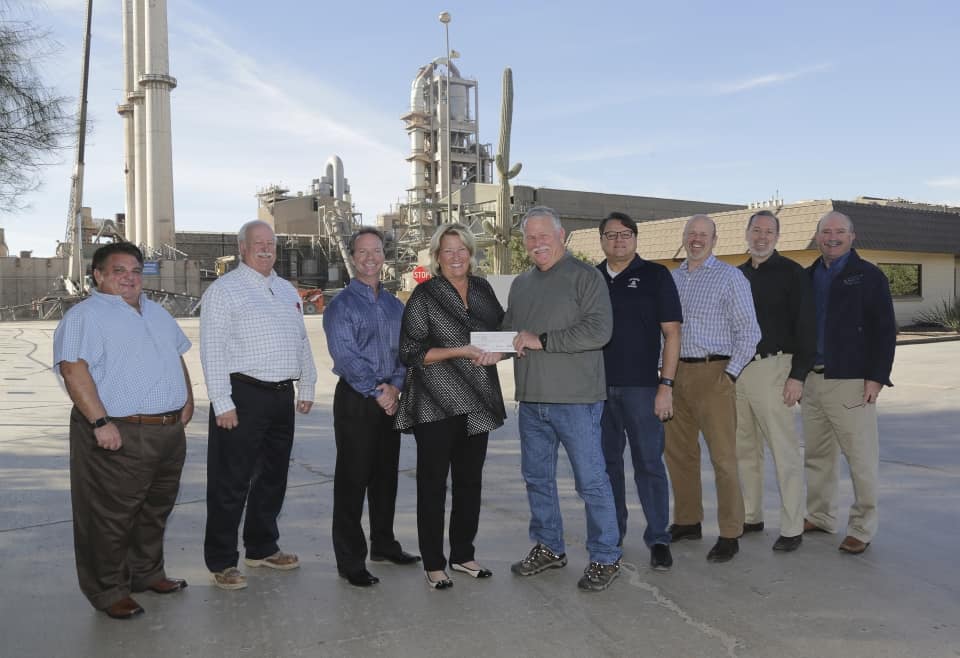

The rebate check was presented by Cathy Ries, vice president customer services & human resources, in attendance from TEP were David Couture, manager of key accounts and Mike Lima senior customer relationship manager.

Receiving the Check was David Bittel, plant manager of the CalPortland Rillito Cement Plant. In attendance from CalPortland; Russell Hawks – plant engineer, Steve Regis – senior vice president, Bruce Shafer – senior vice president, Steve Coppinger – vice president engineering services and William Jerald – chief energy engineer.

About CalPortland

CalPortland Company is a major producer of cement, ready mixed concrete, aggregates, concrete products and asphalt in the western United States and Canada. Founded in 1891 with the principle of providing unsurpassed quality, CalPortland remains a leader in the industry through its commitment to quality, safety, customer service, technical excellence and environmental leadership. The company maintains its headquarters in Glendora, California and operates in the Western U.S. and two Canadian Provinces. For more information about CalPortland Company, visit www.calportland.com.